|

|

|

|

Precision Shape Correction Hydraulic Roller Levelers |

|

|

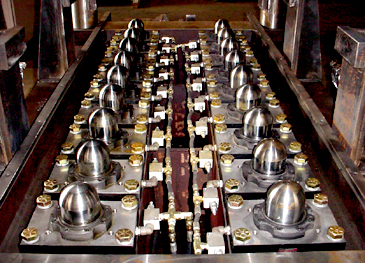

Braner USA Shape Correction Roller Levelers are designed to transform carbon steel, stainless steel, aluminum, and high-performance alloy flat rolled coils into a panel flat strip by eliminating common strip shape defects such as coil-set, wavy-edges, and center-buckle. Braner USA levelers are massive rigid machines capable of precisely applying work roll force uniformly, or at specific points, across the width of the strip.

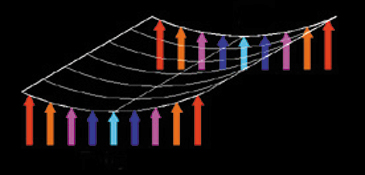

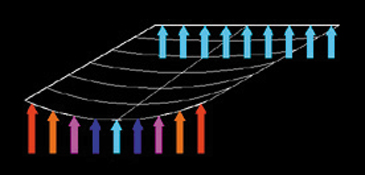

Mechanical leveler bends entry and exit rolls the same amount

Hydraulic leveler bends entry rolls and exit rolls differently The hydraulic cylinders employed to position the back-up flights and lower work rolls are equipped with precision non-contact linear electronic transducers. The electronic transducers have a repeatability accuracy of +0.001% of full stroke, and are designed for 3,000 PSI dynamic and 8,000 PSI static loading pressures. |

Independent hydraulic back-up flight cylinders

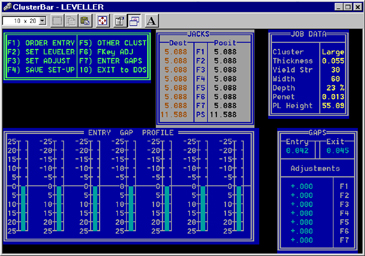

Automatic Leveler Set-Up & Calibration: Braner USA Hydraulic Levelers are equipped with automatic roll positioning, and automatic leveler calibration, features that minimize the "art" of leveler set-up and makes regular calibration quick and easy. Material thickness and yield strength data are entered in the leveler controller via keypad, causing the leveler to automatically adjust to a prescribed entry and exit roll gap ideal for that particular gauge and yield strength. Other commands will adjust the leveler to eliminate center buckle or edge wave. Manual overrides allow the operator to make entry and exit roll gap and roll-bend adjustments on the fly.

Hydraulic leveler data input monitor |

9301 West Bernice Street Schiller Park, IL 60176 (ph) 847.671.6210 (fx) 847.671.0537