|

Precision Electronic Servo Feed: The Steel Warehouse line is equipped with a precision servo driven roll feed to convert coils into precise cut lengths. The Servo Feed employs high traction non-marking feed rolls driven by a 75 HP servomotor while an electronic encoder reads the rotary position of the feed roll to 1/10,000 of a revolution. The servo drive controller uses the electronic signals for commands to accelerate, decelerate, and stop. When the feed roll decelerates to a full stop, the controller sends a signal for the shear to cut the sheet. As the shear ram is returning from the cut, a signal is given for the feed rolls to reverse a few thousandths so the upper shear blade doesn’t swipe the lead edge of the strip. As soon as the shear is “home”, the feed rolls accelerate to feed and measure the next sheet. The cycles/minute capability for a servo roll feed compares favorably to a reciprocating mechanical “hitch feeder” or grip feeder because the servo roll feed runs only forward while reciprocating hitch feeders are traveling backwards for half of the total cycle time. Benefits of a servo roll feed include reduced maintenance requirements and lowered operating costs because of few moving parts, and quicker cyclic rates.

Hi-Speed Crankshaft Shear: A mechanical crank shear is included in the Steel Warehouse line for the ultimate in productivity. A time-tested design employed by respected high-speed shear and press builders, the Steel Warehouse shear employs an AC motor to drive a crankshaft flywheel with a pneumatic clutch/brake utilized accomplish a shear cycle. The 200 RPM flywheel speed is able to accomplish a cut in approximately 1/3 second. Blade clearance for shearing various gauges is accomplished from a single point.

|

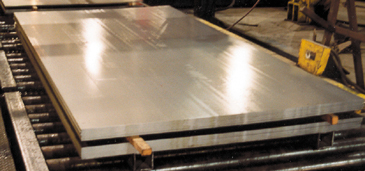

Sheet Stacker: An automatic sheet stacker capable of stacking from 12” wide to 72” wide sheets up to 20’ long into sheet packages weighing up to 20,000 lbs is included in the Steel Warehouse line. An elevating stack table raises the sheet pack to a point just below the lower shear blade to minimize the amount the sheet is dropped after shearing. Power positioned side skirts contain the sheet pack sides while a power positioned end stop squares the package ends. An end discharge power roller conveyor unloads the sheet pack from the stacker, discharging it onto a runout/storage conveyor.

535 W. Forest Hill Ave., P.O. Box 219

Oak Creek, WI 53154

phone: 800-877-8927 fax: 414-764-4803

www.steelwarehouse.com

|