|

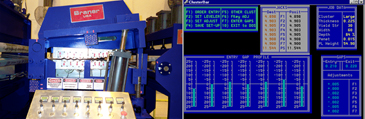

Cluster Leveler: The line includes a "Cluster Leveler," a patented shape correction roller leveler designed to improve, upgrade, or salvage coils with less than desirable strip shape. The Cluster Leveler eliminates strip shape defects such as center buckle, wavy edges, and cross-bow, while minimizing slit edge burr. The Cluster Leveler, equipped with work rolls mounted on close centers supported by multiple independently adjustable back-up flights, employs a combination of close-center work rolls, roll-bending, and strip tension technology to accomplish shape correction. This technology dramatically reduces the strip tension required for shape correction, and as a result strip "necking" (reduction in strip width caused by extreme tension) and "camber" (also caused by extreme tension) is eliminated. The Cluster Leveler is uniquely equipped with work rolls arranged in two "clusters"; a large work roll cluster utilized to level heavy-gauge and high-strength materials, and a small work roll cluster employed to level thin-gauge. Because of its ability to selectively engage large or small work rolls, the Cluster Leveler is able to shape correct a wide range of gauge and yield strength materials without strip necking or inducing camber.

Positioned for coil threading

Positioned for leveling heavy gauge

Positioned for leveling light gauge

|

Industrial duty PLC controls are utilized for full automatic roll positioning based upon gauge and yield strength specifications. Leveler set-up parameters utilized on previously processed coils can be automatically duplicated via job number memory recall, reducing set-up time and reducing trial and error scrap.

Slit Coil Packaging: Slit coils are efficiently packaged for shipment on a Braner USA Automatic Coil Packaging Line capable of handling coils from 1" to 24" wide, weighing up to 10,000 lbs. A Coil Unloading Car removes slit coils from the Recoiler and transfers them to a 4 Arm Turnstile. A Downender removes slit coils one at a time from the Turnstile and places them eye axis vertical onto a power conveyor. Coils are conveyed to a Coiltech/Signode semi-automatic Strapping Machine where multiple ¾" radial straps are quickly applied to each coil. The strapped coils are discharged from the Strapping Machine directly into and ID-OD Coil Stacker that automatically stacks the coils. A 20' diameter multi-station Turntable is utilized to sort various orders. Completed slit coil packages are discharged from the Turntable onto a Weigh Station and Runout Conveyor where packages are weighed, tagged, wrapped, and stored awaiting shipment.

Strapping Machine & automatic Coil Stacker

Schaeffer Industries, headquartered in Temecula, CA, operates coil slitting, leveling/cut-to-length, welded structural tube manufacturing, and coil pickling facilities in Lindon, UT, Mira Loma, CA, and Stockton, CA.

3030 Dulles Drive

Mira Loma, CA 91752

ph: (909)681-1000

fx: (909)360-7197

|