Hydraulic Back-Up Adjustment: The Cassette Leveler employs the 18-independent, micro-processor controlled hydraulic cylinders to establish work roll entry and exit gaps, and back-up flight roll bend adjustments for strip shape correction. Linear electronic transducers precisely position the back-ups for eliminating the wavy-edge and/or center-buckle strip shape defects via work roll bending. A computer memory reduces Leveler set-up time by storing entry and exit work roll gap settings as well as "smile" or "frown" roll bend recipes from previously processed coils. Leveler calibration is automatically accomplished by pushbutton, in a matter of a few minutes without any tools or having to dismantle Leveler components.

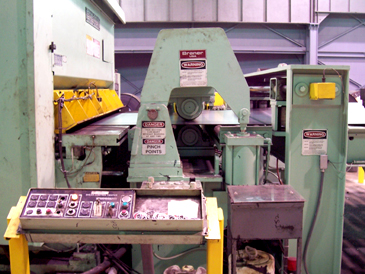

Cassette Leveler Producing Panel Flat Hot Band Sheet

Two Operating Modes: Coil gauges from.050" through 1/2" are processed in two operating modes. Gauges from 1/4" through 1/2" are processd using the 11-roll x 5.500" Cassette in a "tight-line" mode, wherein the strip is laid flat rhoughout the line and the Leveler runs start-stop at 0-160 FPM. A 1,000 PIW x 3/8" wall coil would generate about thirty-seven 20' long sheets, so processing heavy-gauge coil in the start-stop mode is quick and efficient. Processing lighter gauges in the start-stop mode would be inefficient, so the Jemison Demsey CTL Line has the ability to process gauges from .050" to 1/4" with the 17-roll x 3.000" Cassette in a "free-loop" Servo-Feed mode, wherein the Leveler feeds the strip at a constant 200-250 FPM into an accumulation loop. A 93 Kw microprocessor-controlled Servo Roll Feed draws material from the loop, precisely feeds-to-length, adjusts the slack loop depth, and cycles the Shear.

Right to Left: Squaring Guides, Servo Roll Feed & Hydraulic Shear