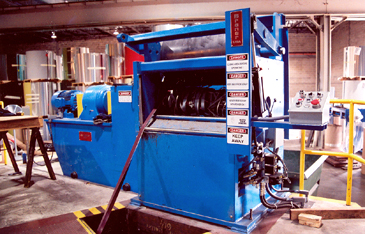

Scrap Disposal: The ATAS Slitting Line employs a zero-tension Scrap Baller to dispose of the edge trip scrap. In order to eliminate scrap edge trim breakage, attendant down-time and oscillated slit coils, the edge trim is directed tension-free into a scrap accumulation pit after the Slitter. The powerful Scrap Baller draws the scrap trim from the accumulation pit and winds the scrap into a tight compact scrap bundle. Scrap bundles are pushbutton ejected from the Scrap Baller into a scrap container.

Massive Scrap Baller Eliminates Scrap Edge Trip Breakage During Slitting

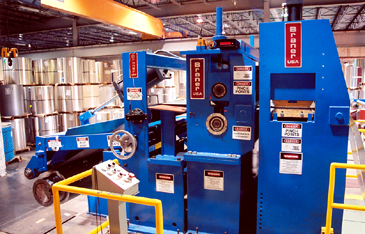

Tensioning Surface-Critical Materials: In order to generate tightly wound straight side-wall coils, the ATAS slitting line is equipped with two tensioning devices: a Pneumatic Pad Tensioner, and a non-marking Roll Tensioner. The Pad Tensioner utilizes felt faced drag pads engaged by pneumatic cylinders to generate winding tension for non-critical materials. The non-marking Roll Tensioner employs special large diameter high-traction coated tension rolls positioned by motorized anti-backlash screw jacks and coupled to water-cooled friction brakes to generate winding tension for surface critical materials such as pre-painted aluminum, copper, zinc, and galvanized coil. The strip tensioning devices can be engaged independently or in tandem, depending upon the materials being processed.

Tandem Pad and Non-Marking Tension Roll Strip Tensioners

Exit End: A pass line/tach roll, Overarm Separator, Strip Threading Funnel, and provisions for a "bolt-in" Guillotine Shear are located at the exit end of the Slitting Line. The pass line/tach roll directs the strip to the Recoiler and senses the strip winding speed and strip footage. Because of the high pass line arrangement, the strip rides above the pass line roll and not under. This eliminates the possibility of surface scuffing or marking. The Overarm Separator frame is supported from both ends making it extremely rigid to assure squareness with the Recoiler. The Overarm arbor swings-out for 2-minute tooling exchanges. A hydraulic cylinder positioned table working in concert with the Overarm mounted deflector forms a funnel to direct slit strips into the Recoiler drum.