Exit End Equipment: The Overarm Separator is solidly attached to the Exit Unit frame to eliminate Overarm frame deflection, with resulting misalignment, that can cause coil sidewall scuffing and coil oscillation. A Coil Splitting Shear is supported on the Exit Unit. A Hydraulic Feed Table acts in concert with an Overarm mounted deflector plate to form a threading "funnel" that guides slit strips directly from the Exit Pass Line Roll into the Recoiler gripper bar. The Recoiler drum is constructed from special hollow forged 2" thick segments heat-treated to Rc 58. A 3" diameter solid steel gripper bar grips the slit strips against a heat-treated serrated steel anvil. The Recoiler includes a massive single-unit parallel shaft helical gear reducer with a huge 14" diameter main shaft.

Exit end view. Notice the clear sight lines from the main operator station.

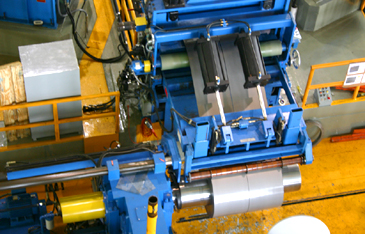

Side Adjust Overarm w/ Safety Tail Hold-Downs: Braner/Loopco mounts the Overarm Separator on the Exit Unit, where the Overarm is supported from both sides, making it more rigid (than a cantilevered Recoiler mounted Overarm), eliminating Overarm deflection that can cause scuffed side-wall coils. A "swing-out" arbor that supports a heat treated "tooling sleeve" allows a re-tooled arbor to be exchanged in less than 2-minutes. The Overarm frame is designed to be adjusted sideways to compensate for minor tooling set-up errors. A Hydraulic Tail Hold-Down snubs the coil OD and secures all coil tails, making OD banding of heavy-gauge hi-strength strips safe.

Rigid Overarm Separator with "swing-out" quick-change tooling arbor and tail hold-downs.

Slit Coil Packaging: 1" wide to 24" wide x 10,000# slit coils are quickly and efficiently sorted and packaged for shipment by a Semi-Automatic Slit Coil Packaging Line. Individual slit coils are removed from the 4-Arm Exit Horn by a "Programmable Operatorless Downender" that automatically travels to a coil group, lifts one coil off the arm, returns to the Conveyor line, and deposits the coil onto the Conveyor.