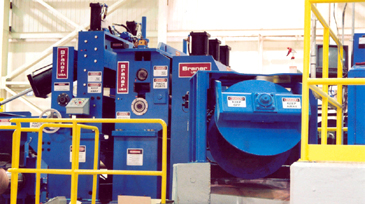

Surface-Critical Strip Tensioning: The Rolled Metal Products line employs two tensioning devices that develop strip tension necessary to produce tight straight-walled light gauge slit coils. A Pad Tensioner is used for tensioning non-critical coil and the non-marking Roll Tensioner is employed when tensioning surface-critical coil. Quick-change entry strip separators guide the slit strips from the looping pit into the Tensioner. The Pad Tensioner is equipped with quick-change friction pads that can be exchanged with fresh pads in one-minute. The Roll Tensioner employs non-marking tension rolls with special roll covers to generate strip tension without surface marking. The tension rolls are equipped with variable tension control and a jog drive for strip threading.

Tension Pad and Non-Marking Tension Rolls can be employed in tandem or engaged independently.

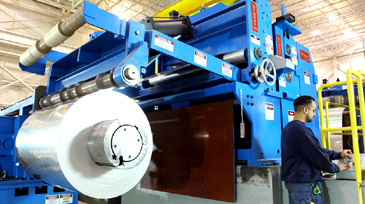

Exit End Equipment: The Overarm Separator is rigidly mounted onto the Exit Unit frame to eliminate frame deflection and resulting misalignment that can cause coil side-wall scuffing and coil oscillation. A heat-treated swing-out tooling arbor allows Overarm tooling to be exchanged in 2-minutes. A "side-adjust" feature allows Overarm alignment to be adjusted while running. An Exit Shear is used to "split" coil ODs and square tail ends. A Feed Table that acts in concert with an Overarm mounted deflector plate forms a funnel to guide slit strips from the Exit Pass Line Roll to the Recoiler gripper bar. A Paper Interleaver can feed pre-cut paper into the rewinding slit coils.

Exit Unit supports the Exit Shear, Side Adjust Overarm, Pass Line Roll, and Paper Interleaver.

16"/20" Recoiler: A large parallel shaft helical gear reducer driven by a 200 HP DC motor powers the Recoiler. The 16" diameter rewind drum is manufactured from heat-treated 2" thick forged steel segments. Lightweight hard plastic Fillers allow Rolled Metal Products to produce 20" ID slit coils.

Coil Packaging: A semi-automatic Slit Coil Packaging Line is employed to strap and package the slit coils. A "wireless" control Coil Car transports coils from the Recoiler to a 4-Arm Turnstile. An "operatorless" Programmable Downender automatically picks-off a slit coil from the Turnstile arm and places the coil onto power conveyor. A coil is automatically conveyed to a Coiltech/Signode Semi-Automatic Strapping Machine that quickly applies multiple radial straps onto the coil. The strapped coil is conveyed and transported to three-coil stacking stations by a coil grab.