The feed sequence continues well past Shear top dead center and stops as the shear blade approaches the strip on the down stroke. The simultaneous Servo Feed-DC Shear cycle expands the feed forward time window and results in a parts per-minute production rate much higher than the conventional start-stop feed-shear mode.

Reject Belt & "Flipper" Sheet Stacker: Cut parts are conveyed away from the Shear on a variable-speed Belt Conveyor. The Belt Conveyor has the ability to direct cut parts into the Stacker or to a scrap cart for discarding head and tail ends. The Stacker carries cut parts on a set of non-marking roller "flippers" until the part is directly above the stack where it is released. The part supporting flippers are pivoted open and closed by air cylinders. An Elevating Stack Table automatically elevates close to the sheet release height to minimize part drop distance. An air float system generates an air film that helps support light gauge parts during the stacking sequence. Pushbutton adjustable side skirts and end stop contain the sheet stacks and produce solid-block packages. A Power Pallet Injector eliminates manhandling heavy pallets into the Stacker. Pallet size is programmed into a controller and the pallet is automatically injected and positioned in the Stacker.

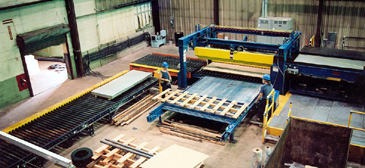

Exit End View of Macsteel 72" x 1/4" CTL Line.

Sheet Pack Handling: In order to avoid production down-time due to finished product packaging, the Macsteel CTL Line employs a Runout Conveyor capable of accumulating more than a dozen pattern sheet packages, and twice as many smaller parts packs. A Rotating Sheet Pack Conveyor receives sheet packs from the Stacker and rotates 90-degrees to align with the Runout Conveyor.

Inspection-Reject Belt, Sheet Stacker and Programmable Pallet Injector.

Precise tolerance panel flat parts, solid-block sheet packs, productivity and bullet-proof reliability made Macsteel's choice of a Braner/Loopco Cassette Leveler Cut-to-Length Line a "no-brainer."

Macsteel Service Centers USA

420 Memory Lane

York, PA 17402

phone: (717) 755-1923 fax: (717) 840-4747

www.macsteelusa.com