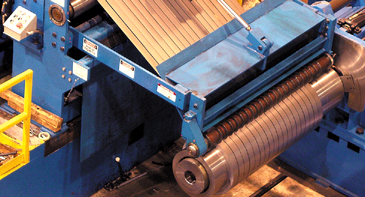

Shape-Correction Cluster Leveler™: A precision Cluster Leveler™ allows Alliance Steel, LLC to supply coil which is free of edge wave and center-buckle shape defects. Multiple diameter work rolls allow the Cluster Leveler™ to correct strip shape defects thoughout the .015" to .250" gauge range, while maintaining precise slit width tolerances. Seven (7) adjustable back-up flights support the work rolls and provide roll bend ability for shape-correction. Automatic Leveler set-up is accomplished by a PLC controller after the operator enters gauge, yield strength, and defect data into a terminal.

With the ability to bend the work rolls via seven (7) adjustable back-up flights, the Cluster Leveler™ does not depend solely on tension for shape correction, and therefore will not "neck" the strip and destroy precision slit width dimensions. The patented corrective Leveler design employs multiple roll "clusters" that contain work rolls ranging in size from 1.500" diameter to 3.000" diameter for effective shape-correction of gauges from .015" through .250".

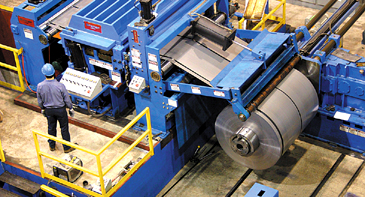

The Cluster Leveler™ is installed between the Slitter and Recoiler. In addition to its shape-correction ability, the Cluster Leveler™ effectively de-burrs the slit strips.

Compact high pass line configuration and precise tension control results in superb slit strip tracking, and allows Alliance Steel, LLC to produce tight, straight sidewall slit coils.

Slit coil Packaging: Alliance Steel, LLC employs an automated Packaging Line to efficiently handle slit coils generated by the Slitting Line. The Packaging Line includes an "operatorless" Programmable Downender that automatically retrieves coils from the Turnstile and places them onto a conveyor line. A Coiltech semi-automatic Slit Coil Strapping Machine quickly applies radial strapping onto the coils.