|

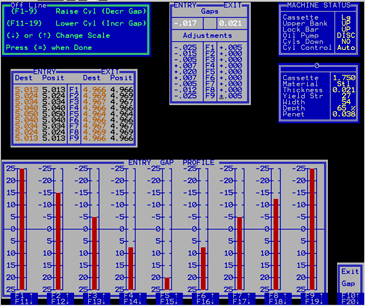

Leveler computer monitor displays an easy to interpret back-up flight bar graph position profile along with material data and Leveler set-up parameters. Multiple monitor screens are interactive and operator friendly.

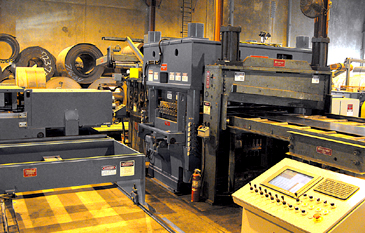

A new free-standing Leveler control station was installed at the exit end of the Cassette Leveler to provide the operator with a clear view to inpsect the leveled strip as it leaves the Leveler. The control station contains the Leveler computer, color monitor, key pad, and joy stick manual override controls.

Electronic Servo-Feed: A high-torque 75 HP Electronic Servo Feed generates the power to efficiently feed and precisely measure the strip for cut-off. The Servo-Feed draws the leveled strip from a free-loop and feeds the strip to a pre-determined length into the cut-off Shear. Part lengths are accurately measured by an electronic encoder, while the microprocessor controls automatically establish ideal acceleration/deceleration rates. Part length and batch count are operator entered into the digital operating system quickly and easily. In addition to the Servo-Feed's precise accuracy and high-cycle rate, the Servo-Feed employs a "pull-back" sequence that pulls the incoming strip away from the Shear blade as the blade withdraws from the strip. As the Shear blade cuts through the strip, the Servo-Feed instantly reverses a few thousandths, pulling the incoming strip away from the Shear blade so the blade doesn't scuff against the leading edge as the Shear completes its cycle. Shear blade scuffing can cause sheet edge damage, bent sheet ends, and lost production related to Shear blade cleaning.

Hi-Performance Hydraulic Shear: Reliance Metalcenter's upgraded CTL Line includes a new high-performance hydraulic cut-off Shear. The new Hydraulic Shear employs PLC controlled hydraulic sylinders to power the guillotine ram through its cycle.

|

Four edge shear blades are installed in the guillotine ram and the lower blade holder. Horizontal blade clearance is adjustable for processing the entire .028" through 5/16" gauge range. Benefits of the Hydraulic Shear include outstanding performance, a virtually silent shearing cycle, and bullet-proof reliability.

The Servo Feed draws the strip out of a free-loop and feeds the strip into the Shear for cut-off. Servo Feeds compare fravorably to "reciprocating hitch feeders" in performance and reliability. Grabbing, releasing, sliding backwards, and re-grabbing consumes the majority of a reciprocating hitch feeder cycle time. By comparison, a Servo-Feed simply feeds forward and has few parts that require replacement or repair. The Servo-Feed's fast, non-reciprocating opreration, low acceleration/deceleration, few moving parts with an absence of chains, screws, clamps, and related mechanical parts makes it an outstanding performer with consistent close-tolerance accuracy, low operating cost, plus bullet-proof reliability.

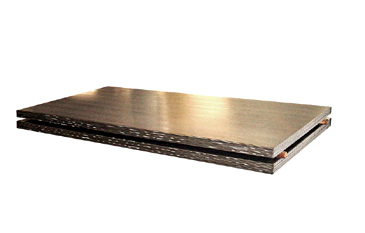

Panel-flat laser quality high-strength sheets, superb performance, plus bullet-proof reliability made Reliance Metalcenter's choice of a Braner/Loopco Cassette Leveler & Servo Feed a "no-brainer.".

Reliance Metalcenter

4355 West 1730 South

Salt Lake City, UT 84127

phone: (801) 974-5300 fax: (801) 973-6928

www.rsac.com

|