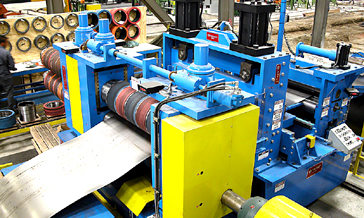

Computer Leveler Controls: Reliance Metalcenter's new Cassette Leveler employs a computer to minimize leveling "black art" and to generate consistent results when run by several machine operators. Automatic Leveler set-up is achieved by entering gauge, yield strength, and strip condition . . . edge wave-center buckle data. Computer override controls allow the operator to make adjustmetnts while running. The computer program stores specific Leveler set-ups for future order number recall, a time and scrap saving feature particularly when leveling partial coils or when breaking into a production run for a quick delivery order.

Turret Head™ Slitters are rugged, precise, and offer bullet-proof reliability. Head change time is less than two-minutes. Searing's "threadless" tooling lock nuts allow re-tooling to be accomplished in less time, and time lost to arbor/nut thread repair is completely eliminated.

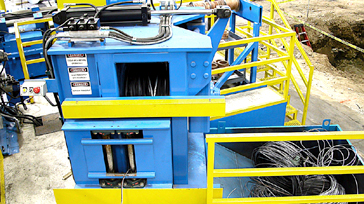

Scrap Disposal: Searing Industries' Slitting Line empoys a pair of massive 1/2" Hydraulic Scrap Winders to handle and dispose of side trim. The Winders are specifically designed to accomplish side trim threading and scrap bundle disposal easily and quickly. The Winders offer bullet-proof reliability and virtually zero maintenance and set-up costs and zero tooling cost.

Special Heavy-Gauge Scrap Winders designed for quick and easy threading and scrap bundle disposal offer bullet-proof reliability and viertually no down-time related to repairs, maintenance, and tooling costs.

Exit End: Searing Industries' Slitting Line is equipped with a Pad Tensioner that generates strip tension necessary to generate tight straight-wall slit coils. Tension is adjustable and regulated from the main operator console. Special quick-exchange tension pads can be swapped in 60-seconds when the friction surface is worn. The Overarm Separator is rigidly attached from both inboard and outboard sides to the Exit Unit base frame, which eliminates Overarm frame deflection and misalignment that can result in coil side-wall suffing and oscillation. Hydraulic cylinder engaged polyurethane Coil Tail hold-Down pads firmly capture the heavy gauge coil tails to prevent coil tail clock-springing while installing OD coil banding.