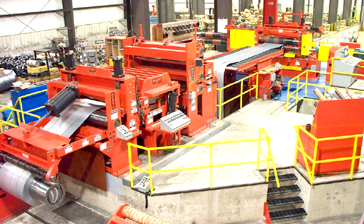

Walworth, WI - Dalco Metals, Inc, a flat rolled steel distributor and coil processor installed a new high-performance Double-Loop Turret Head™ Slitting Line equipped with a Shape-Correction Cluster Leveler™ in its newly expanded Walworth, WI facility. The new line has the ability to slit and shape correct 50,000# x 65" wide hi-strength HR pickled, cold rolled, and galvanized carbon steel coils in gauges from .187" through .010" at processing speeds to 1,000 FPM.

Dalco Metal's new Turret Head™ Slitting Line equipped with a Computer Controlled Cluster Leveler™ produces precise tolerance slit coils while correcting edge-wave, center-buckle, and cross-bow strip shape defects. The new Slitting Line joins a Braner 1/4" Turret Head™ Slitting Line and a Braner 1/4" x 72" Hydraulic Cassette Leveler Servo Feed CTL in Dalco's Walworth, WI facility.

Multiple Operating Modes: The new line allows Dalco Metals to choose from four (4) processing modes: Double-Loop; Single-Loop; Push-Pull; and Tight-Line; and to process coils using the mode that generates the highest quality product. Surface-critical thin gauge coil can be processed in a Double-Loop mode where the Uncoiler drives the strip into a free-loop. This mode processes coils with zero back-tension and eliminates Slitter tooling slippage that could cause surface scuffing. Single-Loop mode can be employed for processing mid-gauges, and a Tight-Line can be utilized for edge trimming and full coil shape-correction. A Push-Pull mode is ideal for heavy slitting loads with hi-strength heavy gauge coil.

The Uncoiler is equipped with a large loop-control DC motor that can be used to generate back-tension or to drive the strip into a free-loop for tension-free unwinding. A sonic loop sensor, Pinch Rolls, pushbutton adjustable Side Guides, Automatic Edge Guide, and Crop Shear are mounted on the compact Entry Table.