Coil Processing Equipment

With a history of innovation that originated in 1956, Braner USA has earned a reputation for supplying bullet-proof reliable state-of-the-art ferrous and non-ferrous Coil Processing Equipment, including Coil Slitting Systems, Cut-to-Length/Blanking Systems, Precision Roller Levelers, Precision Stretch Levelers, Automated Coil Processing Lines, Oscillate Coil Systems, Strip Rolling Systems, and purpose-built engineered flat rolled strip processing equipment and systems.

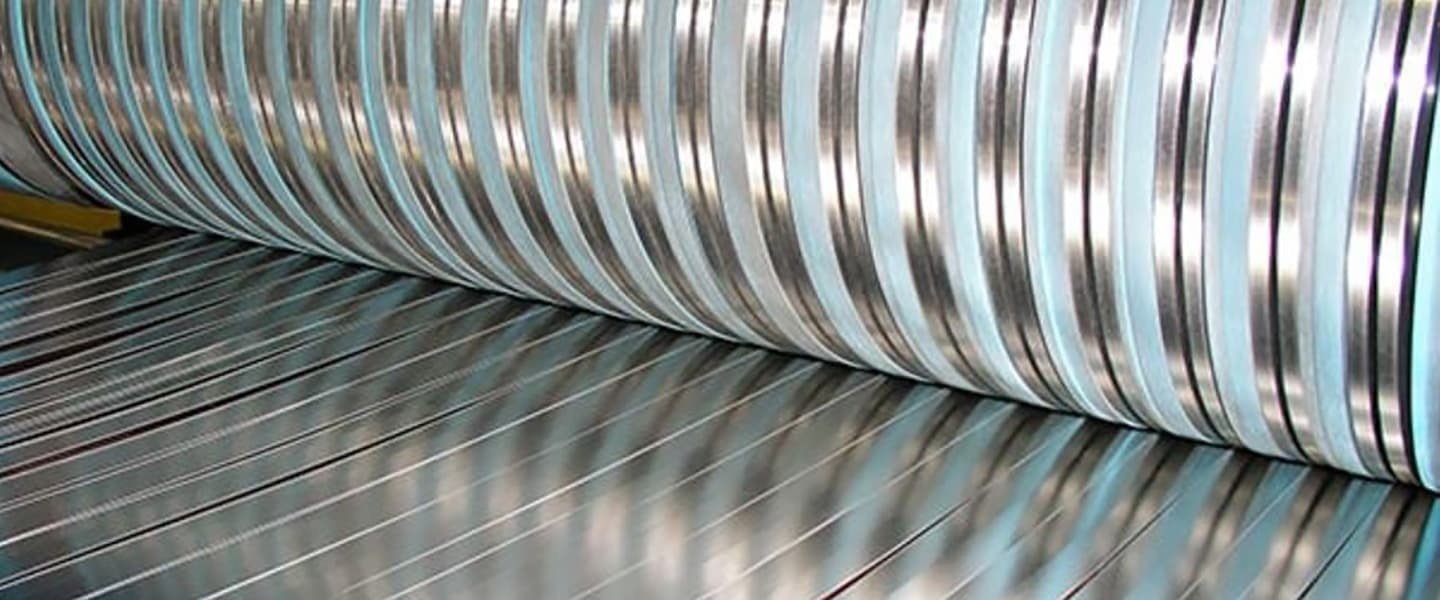

Our Slitting Lines are centered around the exclusive Turret Head™ Slitter, patented in 1972.

Learn More

Braner USA Coil Packing Lines automate the end-of-line process with precision stacking, strapping, and protective packaging.

Learn More

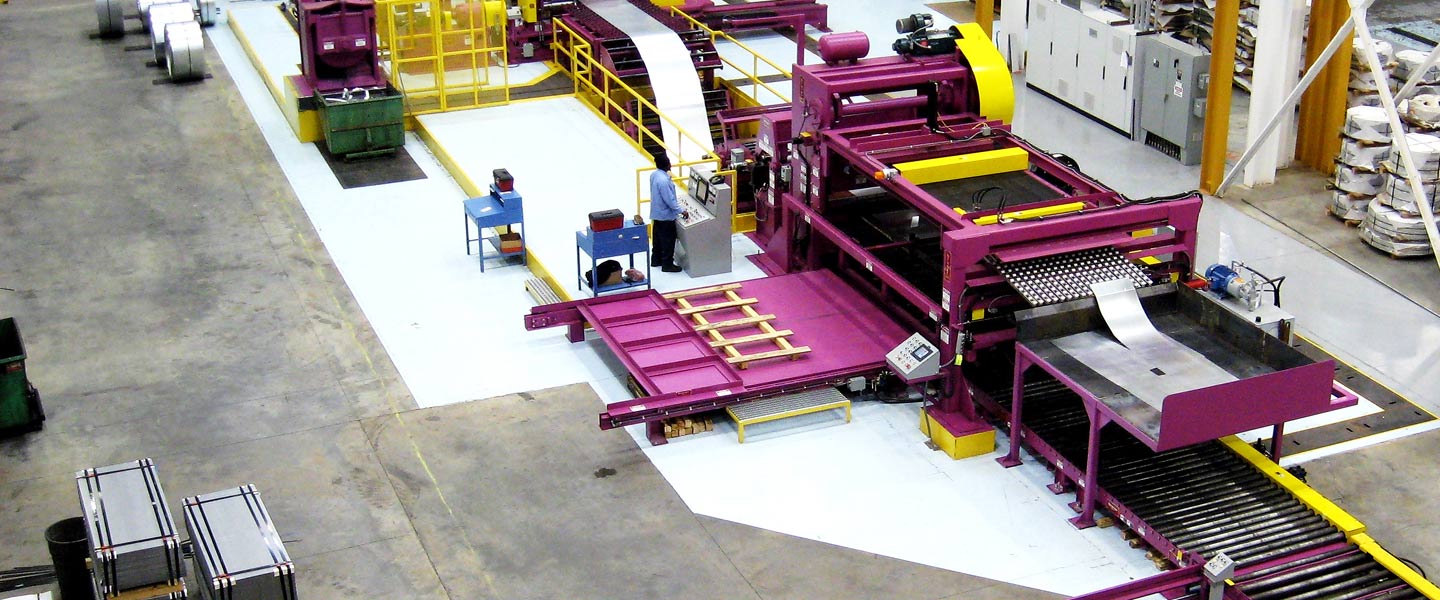

Braner USA Cut-To-Length (CTL) Lines are engineered to convert steel coils into precision sheets and plates with exceptional flatness and efficiency.

Learn More

Braner USA Multi-Blanking Lines are custom-engineered coil processing systems that unwind, level, slit, and shear coiled metal into precision blanks.

Learn More

At Braner USA, we’re not just a machine builder—we’re an engineering company at our core.

Learn More

Braner USA retrofits critical terminal equipment—including turnstiles, coil cars, uncoilers, shears, prep stations, and recoilers—into aging or outdated coil processing lines.

Learn MoreServices We Offer

Our expert technicians are not limited to providing service exclusively for Braner coil processing equipment. Our expertise allows us to provide service and support for almost all metal processing equipment brands.

Crafting the World’s Finest Coil Processing Systems

Braner USA’s core strength is the experience, know-how, and dedication to performance, product quality, production efficiency, and customer satisfaction. Braner USA’s engineers, designers, technicians, and trade craftsmen with decades of experience and an obsessive focus on ultimate satisfaction of Braner USA’s coil processing equipment users, coordinate and collaborate to craft the world’s finest metal processing systems.

Customization Over Commoditization. Our systems process coils from 0.005" aluminum to 0.750" high-strength steel, handling coil weights up to 50 tons and widths up to 120". Each automated coil processing line is engineered to meet unique performance specs and integrate seamlessly into your operation.

Designed to Produce, Built to Last. Braner USA has earned a global reputation for building high performance coil processing lines tailored to each customer’s production needs. With over 1000 installations in 25+ countries, our equipment is engineered for strength, reliability, and long-term productivity.

From turret head slitter and precision levelers to full-line diagnostics and remote troubleshooting, our controls are designed to reduce downtime, maximize throughput, and empower operators with smarter interfaces. We offer advanced features integrated into our equipment including tooling robots, robotic debanding, hands-free threading with our patented Andiamo systems, automatic separators, integrated shift reporting, and more - delivering cutting edge performance while keeping operator safety at the forefront.

Explore Our Gallery

Explore our gallery to see Braner USA coil processing equipment in action. From advanced slitting lines and stretch levelers to custom coil handling systems and precision tooling, every image highlights the craftsmanship, engineering, and performance that define our machines. Whether on the shop floor or in the field, our solutions are built to perform, built to last, and built to move the steel industry forward.

Give us a call or fill out the form and one of our team members will be in touch as soon as possible.

9301 W. Bernice Ave

Schiller Park, IL 60176