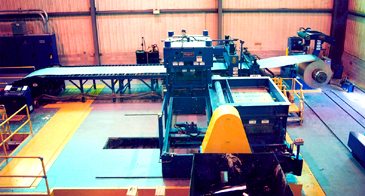

York, PA – Macsteel Service Centers USA has installed a high-production Braner/Loopco Cassette Leveler Servo Feed Cut-to-Length Line in its York, PA metal distribution facility. The new Cut-to-Length Line converts 60,000# x 72" wide carbon steel, stainless, and aluminum coil in gauges from .019" through .250" into panel-flat close-tolerance parts. The CTL Line is equipped with Computer Controlled Cassette Leveler, a Precision AC Servo-Feed, and a variable speed DC Shear capable of producing close-tolerance parts at production rates exceeding 80-parts/minute.

60,000# x 72" x 1/4" Cassette Leveler Servo-Feed DC Shear CTL Line.

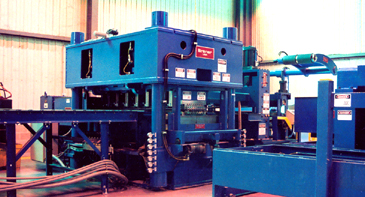

Cassette Leveler: A "Cassette" Leveler allows Macsteel to produce shape-corrected panel flat parts throughout a wide gauge and product range. Microprocessor controlled hydraulic back-up positioning cylinders are housed within a massive 4-post Leveler frame into which quick-change Leveler Cassettes are installed. The exchangeable Cassettes contain all the working Leveler parts . . . work rolls, back-up flights, and drive shafts, in a common housing installed into and removed from the Leveler frame. Cassettes are hydraulically locked into the Leveler frame, and adjustable Cassette back-up flights are automatically aligned with the hydraulic back-up cylinders. Work roll drive shafts are automatically engaged with the Leveler drive gear box as a Cassette is installed. Once a Cassette is installed, a microprocessor automatically accomplishes Leveler set-up based upon material specifications. The Cassette Leveler employs microprocessor controlled hydraulic cylinders rather than motor, gear reducer, sliding wedge, and jack screws to make Leveler work roll adjustments. The hydraulic cylinders are installed at the entry and exit ends of each back-up flight. Precision electronic linear transducers are employed to independently position each of the cylinders. Adjusting the entry end and exit end cylinder elevations causes the work rolls to be "tilted" front-to-back for coil-set correction. Adjusting back-up flight cylinder elevations from side-to-side accomplishes "roll-bend" for precise edge-wave and center-buckle shape correction. Hydraulic Leveler benefits include elimination of mechanical screw-wedge backlash and maintenance, automatic Leveler set-up, job set-up recall memory, automatic Leveler calibration, and bullet-proof reliability.

Precision Microprocessor Controlled Hydraulic Cassette Leveler.

The Macsteel Cassette Leveler is equipped with a 3.000" x 17-roll x 5-Hi Cassette for leveling .250"-.060" gauges, and a 1.500" x 17-roll x 5-Hi Cassette for .075"-.019" gauges. 5-Hi Cassettes allow Macsteel to process cold rolled carbon steel, stainless, and aluminum coil. Cassettes are stored on a 2-Cassette Injector Car that exchanges Cassettes in about 2-minutes. A Power Cassette Maintenance Opener "opens" a Cassette to expose all working parts for periodic cleaning and maintenance.