|

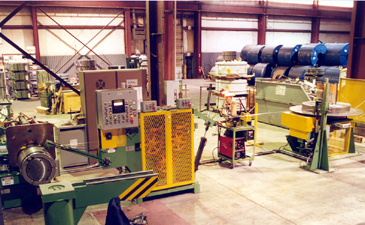

Tulsa, OK - Steel Coil Services, a division of Fintube Technologies, Inc, has installed a large high-speed Traverse Coil Winding System in its Port of Catoosa, OK, coil processing facility. The high-speed system, designed and manufactured by Stanat Precision Machine Co, Schiller Park, IL, is capable of producing jumbo size traverse wound coils at line speeds up to 1,500 FPM. Metal stampers and roll formers prefer to feed production lines with traverse wound coils rather than conventional ribbon wound slit coils because traverse wound coils contain ten (or more) times the lineal strip footage as a conventional ribbon wound coil, which reduces production losses related to coil loading and threading. In addition to containing 10 times the strip footage, wide traverse wound coils are easier to transport and safer to handle than large diameter narrow slit coils.

The Steel Coil Services Traverse Winding System is capable of processing 70,000 PSI yield strength carbon and stainless strip in gauges from .028" through .060", in widths from 3/8" through 3/4" into 6,000# x 21" wide traverse wound coils. The system can generate traverse wound coils up to 60" diameter without side plates or coil spools to contain the coil. Traverse wound coil can be produced with or without cardboard coil ID cores.

High Speed "Vertical" Uncoiler: The production of large traverse wound coils is a process during which a succession of narrow slit coils are individually unwound, butt-welded end to end, and traverse rewound until the specified traverse wound coil size is achieved. Rather than loading one narrow coil at a time onto an uwinder, a common method of feeding a Traverse Winding System is to load a group of multiple coils onto a mandrel type uncoiler, then unwinding one coil at a time.

|

Once one coil is unwound, the entire coil group is shifted horizontally to align the next coil. High speed unwinding a single coil from a multiple coil group is often troublesome, as the coil being unwound tends to "wobble" on the uncoiler drum, rubbing against the adjacent coil and creating strip tracking problems.

Slowing the line speed solves that problem at the cost of productivity. The Steel Coil Services system is equipped with a unique Uncoiler that supports a 15,000# coil stack in an "eye-vertical" position rather than the usual "eye-horizontal" position. The Vertical Uncoiler eliminates narrow coil wobble, adjacent coil scuffing, and coil group shifting, allowing the line to run narrow coils at 1,500 FPM. The slit coil stack can be processed with or without a pallet. A hydraulically actuated multiple segment expanding mandrel centers and secures the eye vertical coil stack, and a vertically adjustable strip guide provides positive control of the unwinding strip. The Uncoiler is equipped with a reversing jog drive for coil positioning and an adjustable tension brake.

Strip End Joiner/Butt-Welder: Because a traverse wound coil consists of multiple ribbon slit coils joined end-to-end, an efficient method for joining individual coils is necessary.

|