The Steel Coil Services system is equipped with a portable high speed "flash-welder" that joins the coil ends together. Coil joining time is about a minute. The tail end of one coil and the lead end of the succeeding coil are clamped in the welding dies, and after the strips are aligned the automatic welding cycle is initiated. A weld annealing feature is included. The End Joiner is portable and is moved out of the line when running.

Strip Pulling Bridle: Power to pull coils off the Uncoiler at 1,500 FPM is provided by a heavy-duty Pulling Bridle. A Pulling Bridle is required in Traverse Coil Winding Systems because traverse winding tension is extremely critical and unrelated to the strip tension required to control unwinding. Therefore the entry and exit strip tensions must be independently regulated. The Bridle contains multiple large diameter DC motor driven rolls arranged to provide large wrap angles for positive strip traction. Pneumatic contact rolls secure the strip against the bridle rolls during strip joining and coil unloading when strip tension is released. The Bridle is equipped with power sufficient to edge condition the strip in the future. Adjustable entry and exit strip side guides and an adjustable elevation entry pass line roll position the strip in and out of the Pulling Bridle.

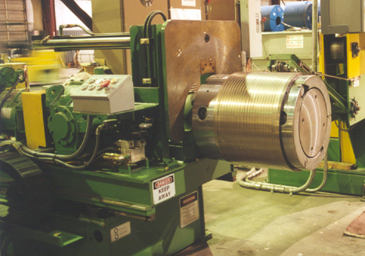

Servo Traverse Winder: The Traverse Winder is the unit that generates various size traverse wound coils. The Winder is equipped with a 20" diameter hydraulic expanding drum with a powered strip gripper bar. The drum can rewind coils directly onto the drum or onto a cardboard core. Finished coils are discharged via hydraulic coil pushoff onto a Single Arm Turnstile. The winding drum is powered by a DC motor drive with variable tension control that allows formation of large diameter traverse wound coils without the need for side support plates or coil spools. The traversing rewind drum and drive base shifts on precision linear guide rails and anti-friction recirculating bearing trucks.

|

This system is more accurate, requires less maintenance, and requires less motive force than conventional friction box or dovetail slide designs. As the Rewinder traverses back and forth, the strip is guided directly onto the coil by a cantilevered guide arm with a unique constant pass line roll assembly.

This system is more accurate, requires less maintenance, and requires less motive force than conventional friction box or dovetail slide designs. As the Rewinder traverses back and forth, the strip is guided directly onto the coil by a cantilevered guide arm with a unique constant pass line roll assembly.

Microprocessor Operator Control: An operator friendly microprocessor controls the Traverse Winding System. The operator enters the strip gauge, width, gap between wraps, helix angle, strip stagger, coil end dwell, and the overall traverse coil width into the controller key pad to produce various size and density traverse wound coils. A message display provides data input prompts and confirms commands. A 100 order "databank" is included for recalling parameters from previously run jobs, eliminating set-up time.

5151 N. Skiatook Road

Catoosa, OK 74015

phone: 918-266-5151 fax: 918-266-5154

|