Surface Inspection: A unique Surface Inspection Tower provides the means for Mi-Tech to visually inspect the top side and the bottom side of the strip as the coil is processed. High-intensity fluorescent lamps and electronic strobe lamps provide the lighting for top and bottom surface inspection. Large diameter non-marking bridle rolls installed in a hydraulic elevating tower raises the strip pass line so that the top and bottom of the strip can be inspected while the strip is moving vertically. The tower rolls are lowered during strip threading and slitting, and elevated while performing surface inspection.

Top & Bottom Surface Inspection Tower

Strip Tensioning: Multi-cut rewind tension is generated from a Pneumatic Pad Tension Stand and a Non-Marking Roll Tension Stand. Either or both strip tensioning means can be employed depending upon the job being performed. The strip tensioning equipment is capable of processing both dry and oiled-lubricated strip.

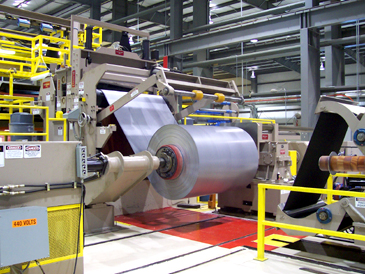

Recoiling: The Mi-Tech Recoiler is capable of over rewinding and under rewinding at 1,000 FPM. A 300 HP-DC drive provides rewind tension. In order to assure perfect side-wall registration while rewinding full width coils, the Recoiler is equipped with a hydraulic shifting base and an automatic edge tracking system. A floor mounted Outboard Support eliminates shaft deflection and vibration in all operating modes. The collapsible Recoiler drum is equipped with 2" thick forged clamshell segments heat-treated to Rc58 for wear resistance. A 3" diameter hydraulic gripper bar secures slit strips in the drum. Slit coils are guided onto the Recoiler drum via a quick-change Overarm Separator with a side-adjust feature.

Automatic Tracking Recoiler w/ Over and Under Rewind Capbility