A huge productivity benefit comes from the fact that a slitter set-up for the next order is accomplished while the line is running, not after an order is processed and the line is shut down. Like all Turret Head Slitters™, head changes are accomplished in less than 2-minutes and reliability is "bullet-proof."

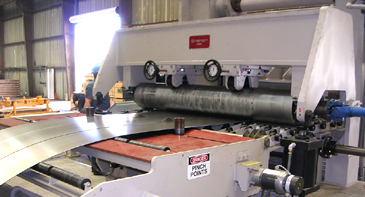

Precision Electronic Servo Feed: The Pacific Toll Precision Electronic Servo Feed employs high-traction, low-inertia, non-marking feed rolls driven by a microprocessor-controlled AC servo motor to feed and measure parts to +/- 0.005" length tolerances. The Leveler runs at a constant speed feeding the leveled strip into large radius non-marking quadrant tables that support the strip in and out of the loop. The Servo Feed draws the strip from the free-loop and feeds the strip to a pre-set dimension into the Shear. A brushless AC servo motor drives both upper and lower feed rolls through a zero-backlash drive train. The part length is precisely measured by an electronic encoder, while a microprocessor establishes acceleration/deceleration rates. Sheet length and batch count are quickly entered into the digital operating system. Compared to a mechanical "reciprocating mechanical feed," a Servo Feed has a much higher production rate and much lower maintenance requirements. A reciprocating feeder grabs the strip, shoves it forward to a positive stop, grabs it with holding clamps, shoves the reciprocating clamp backwards, grabs the strip again, and releases the holding clamp before it starts another cycle.

Hi-Cyclic Rate Electronic AC Servo Feed

Grabbing releasing, sliding backwards, and re-grabbing consume the majority of a reciprocating feeder's cycle time. By comparison, a Servo Feed simply rotates its feed rolls to advance the strip. A reciprocating mechanical feed's productivity is diminished further when making multiple feed strokes for long parts. The Servo Feed's non-reciprocating operation, low acceleration/deceleration rate, few moving parts (and a total absence of chains), length adjust screws, shock absorbers, limit switches, valves, pumps, slides, clamps, & hydraulic hoses give it "bullet-proof" reliability, as well as consistent accuracy.

100-Cycle/Minute DC Shear: The Pacific Toll line includes a huge top driven bow-tie Shear powered by a variable speed DC motor. The Shear is capable of producing pattern-size sheets in a 60-stroke/minute "clutch-brake" mode, and short blanks in a "non-stop continuous-stroke mode."

The Servo Feed/Shear cycle is programmed to operate in the clutch-brake mode for long parts, and the non-stop continuous-cycle mode when producing shorter parts. Combined with the high-cyclic rate Servo Feed, the non-stop continuous Shear cycle offers unrivaled close-tolerance small blank productivity. When the Shear runs non-stop, the crankshaft speed is synchronized with the Servo Feed, and the Servo Feed cycle begins as soon as the upper shear blade clears the material on its upstroke. The simultaneous Servo Feed-DC Shear cycle can generate parts per-minute productivity twice as high as any other technology.