|

Flat strip supported on the Exit Quadrant and entering the Strip Guides.

Precision Servo Feed: Two-sets of widely spaced roller side guides center the strip into the Servo Feed. The guides also assure the strip is square with the Servo Feed in order to maintain precise diagonal blank tolerances. A high-traction non-marking Servo-Feed powered by a precision microprocessor controlled AC servo motor feeds and meters the surface-critical strip to precise length tolerances. The Servo-Feed draws the leveled strip from the free-loop and feeds to a pre-set length through the Shear. Part lengths are precisely measured by a digital encoder, while a microprocessor automatically establishes ideal acceleration/deceleration rates. Part length and batch count are key pad entered into the digital operating system. Servo Feeds compare favorably to "reciprocating mechanical feeders" in productivity and reliability. A reciprocating mechanical feeder grabs the strip, shoves forward to a positive stop, engages holding clamps, shoves the reciprocating clamp backwards, grabs again and releases the holding clamp before starting another feed cycle. Grabbing, releasing, sliding backwards, and re-grabbing consumes the majority of a reciprocating feeder cycle time. By comparison a Servo-Feed simply rotates feed rolls in one direction. The need to make multiple reciprocating feed cycles further diminishes a reciprocating mechanical feeder's productivity when producing long parts. The Servo-Feed's non-reciprocating operation, low acceleration/deceleration rate, few moving parts, and a total absence of chains, length adjust screws, shock absorbers, limit switches, valves, pumps, slides, clamps, & hydraulic hoses gives it consistent accuracy and "bullet-proof" reliability.

Hi-Cyclic Rate Precision Electronic AC Servo-Feed processing hi-strength surface-critical strip.

Hi-Speed Shear: The Greer Steel CTL Line employs a hi-speed Hydraulic Shear to cut 120,000 PSI shear strength parts to length. The Hi-Speed Hydraulic Shear is capable of a 60-strokes/minute cyclic rate, which is comparable to a mechanical shear cyclic rate. The Shear employs PLC controlled hydraulic cylinders to drive the upper guillotine ram through the cutting cycle. 4-edge shear blades are mounted on the guillotine ram and the lower blade holder. Blade gap is adjustable from a single point for processing the range of gauges and mechanical properties. Because the Shear employs cylinders rather than a pneumatic clutch and brake to drive the ram, the shearing cycle is virtually silent. The Greer Steel Shear is fast, has a virtually silent shear cycle, and the few moving parts offers "bullet-proof" reliability.

|

Hi-Speed Hydraulic Shear offers speed, silent cycle, and bullet-proof reliability.

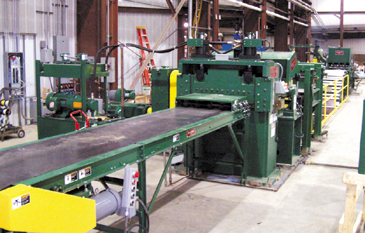

Runout Belt: Sheared parts are transported away from the Shear on a variable-speed Belt Conveyor. Because the CTL line is primarily employed to produce special order surface-critical mini-blanks rather than hi-tonnage pattern sheets, part stacking is accomplished manually. Although hand-stacking is not "state-of-the-art", it is a failure-proof method for stacking 4" x 12" (for example) mini-blanks, and allows several mini-blank stacks to be neatly and efficiently piled onto a common pallet. Surface-critical precision blanks must be closely inspected to avoid rejections, and manual stacking accomplishes the inspection of each and every part without additional manpower.

CTL Line generating precision mini-blanks.

Productivity and bullet-proof reliability make the choice of a Braner/Loopco Cut-to-Length Line a "no-brainer."

Greer Steel Company

624 Boulevard

Dover, OH 44622

phone: (330) 343-8811 fax: (330) 364-5624

www.greersteel.com

|