Saline, MI – ThyssenKrupp Materials NA, a large non-ferrous coil distributor and processor has installed a new Braner/Loopco Automatic Slit Coil Packaging System in its new Saline, MI, facility. The new Coil Packaging System efficiently handles and packages stainless, aluminum, brass, and copper slit coils produced from ThyssenKrupp's Braner/Loopco Turret Head™ Slitting Line. Slit coils range in size to 10,000# x 24" wide up to 74" OD with coil IDs of 16" and 20".

"Wireless" Control Coil Unloading Car: A Coil Car unloads finished slit coils from the Slitting Line Recoiler and transfers the slit coil group to a 4-Arm Turnstile at the entry end of the Packaging System. The Car is equipped with adjustable narrow coil support stanchions that stabilize and secure the slit coil group during the coil transfer. A hand-held "wireless" Coil Car control provides excellent operator control mobility and allows the Car to be operated from a safe distance.

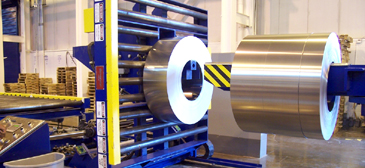

Wireless control Coil Car transferring slit coils from the Slitting Line to a 4-Arm Turnstile.

"Operatorless Ptogrammable Slit Coil Downender: The 4-Arm Turnstile positions the slit coil group at the unloading station where a Slit Coil Downender removes individual slit coils one at a time from the Turnstile arm and deposits individual coils onto a powered roller conveyor. The Downender is controlled by a programmable controller into which the width of each slit coil at the Turnstile unloading station is entered via operator console keypad. After all coil widths are entered, the Downender:

The coil downending cylcle is full automatic and operatorless after the coil widths are entered into the programmable controller keypad.

Programmable Slit Coil Downender automatically separates and downends coils.

Automatic Coil Staging Conveyor: Slit coils discharged from the Downender are conveyed to a Strapping Machine via Power Roller Conveyor. The Conveyor is designed to stage four 74" OD coils between the Downender and the Strapping Machine, and is comprised of four separately driven conveyor sections, with each section independently controlled. Coil advancing to the Strapping Machine is fully automatic.