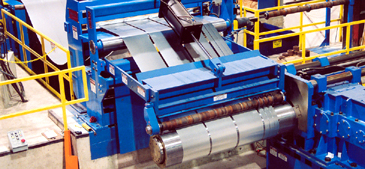

The Overarm Separator is rigidly mounted onto the Exit Unit frame to eliminate Overarm frame deflection and resulting misalignment that causes coil side-wall scuffing and coil oscillation. A quick-change "swing-out" Overarm arbor allows pre-tooled arbors to be exchanged in 2-minutes. A Hydraulic Threading Funnel directs slit strips from the Exit Pass Line Roll into the Recoiler gripper bar during threading.

Compact High Pass Line provides superb slit-strip tracking, regardless of strip width, gauge, or number of cuts.

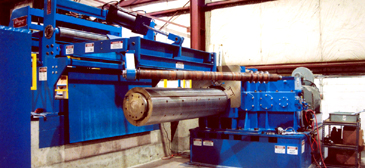

Recoiler: A 250-HP 2-ratio Recoiler is equipped with a massive Recoiler drum manufactured from custom forged 2" thick segments hardened to Rc 58. A 3" diameter solid steel gripper bar grips slit strips against a heat-treated serrated steel anvil. The Recoiler drum is mounted on the 14" diameter output shaft of a 250-HP 1.2 service factor parallel shaft helical gear reducer.

Massive 250-HP, 2-Ratio Recoiler has a 14" diameter main shaft and a full-face ground surface coil pushoff.

Unique swing-out Overarm arbor allows pre-tooled Overarm arbor exchange to be accomplished in minutes.

Quality, Productivity, Bullet-Proof Reliability, know-how from building nearly 600 Slitting Lines, plus outstanding technical support made Lafayette Steel Sales' selection of a Braner/Loopco Turret Head™ Slitting Line over all others a "no-brainer".

Lafayette Steel Sales

2407 North Ninth Street Road

Lafayette, IN 47903

phone: (765) 423-5371 fax: (765) 742-2743