Cluster Leveler™: A 72" x 4-Hi x 7-flight Precision Cluster Leveler™ allows Hascall Steel to supply its customers with coil free of wavy-edge and center-buckle strip shape defects. The patented Leveler design has multiple roll "clusters," with work roll sizes ranging from 1.500" to 3.000", which allow it to correct strip shape defects throughout the Slitting Line's .015" to .250" gauge range. Seven (7) adjustable back-up flights support the work rolls and provide roll bend ability. Automatic Leveler set-up is accomplished by a PLC controller after the operator enters gauge, yield strength, and defect data into the terminal.

Specifically designed for coil-to-coil applications, the Cluster Leveler™ employs non-driven work rolls. The hydraulic cylinder "quick-open" feature allows coil threading to be quickly accomplished.

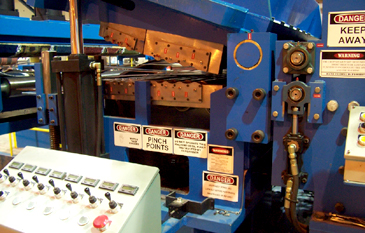

Pushbutton Overarm Tooling Lock-Up: The Overarm Separator swings open to align with a tooling set-up cart, where Overarm tooling set-ups are made off-line, while the Slitter is running. Tooling is transferred from the Overarm arbor onto the Gatling Gun type set-up cart, and the tooling for the next order is quickly transferred onto the Overarm arbor. Once loaded, the Overarm tooling is locked onto the arbor by pushbutton.

Swing-Open Pushbutton Tooling Lock-Up Overarm Separator and Gatling Set-up Cart.

Quality, Productivity, Bullet-Proof Reliability, know-how from building nearly 600 Slitting Lines, plus outstanding technical support made Hascall Steel's selection of its third Braner/Loopco Turret Head™ Slitting Line a "no-brainer".

Hascall Steel Company

4165 Spartan Industrial Drive

Grandville, MI 49418

phone: (616) 531-8600 fax: (616) 531-7555

www.hascallsteel.com