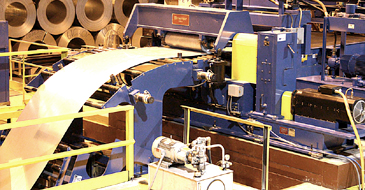

Precision Electronic Servo-Feed: An Electronic Servo Feed driven by a high-cyclic rate precision AC servo drive feeds and meters strip to precise length tolerances. The Servo-Feed draws the leveled strip from a free-loop and feeds the strip to a pre-determined length through a Hi-Speed cut-off Shear. Part lengths are precisely measured by an electronic encoder, while a microprocessor automatically establishes ideal acceleration/deceleration rates. Part length and batch count are entered into the digital operating system quickly and easily.

Servo Feed "Pull Back" Sequence: In addition to the Servo-Feed's precise length accuracy and high-cycle rate capability, the Servo-Feed employs a "pull-back" sequence that pulls the incoming strip away from the upper Shear blade as the Shear blade leaves the strip after the cut. As soon as the upper blade cuts through the strip, the Servo-Feed reverses .003", pulling the incoming strip back from the Shear blade so the blade doesn't scuff the leading strip edge as the Shear completes its cycle. Shear blade scuffing often cause sheared edge damage, bent sheet ends, and down-time related to Shear blade cleaning.

Hi-Performance Electronic AC Servo-Feed features a high cyclic rate and a "pull-back" sequence that avoids Shear blade scuffing.

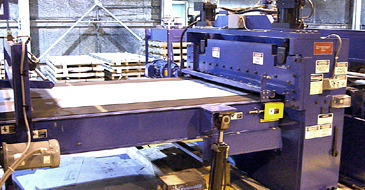

Hi-Speed Hydraulic Shear: Macsteel's CTL Line is equipped with a high-speed hydraulic cut-off Shear capable of 60-strokes/minute. The Shear employs PLC controlled hydraulic cylinders to drive the upper guillotine ram through its cycle. Four edge blades are mounted onto the guillotine ram and the lower blade holder. Horizontal blade clearance is adjustable for processing the entire .019" through .250" gauge range. Benefits of the Hydraulic Shear include excellent performance, a virtually silent shearing cycle, and low operating cost.

Hi-Speed Hydraulic Shear offers excellent performance and silent operation.

Inspection/Reject Belt: Cut sheets are carried away from the Shear on a variable-speed Inspection/Reject Belt Conveyor that provides a convenient station from which to visually inspect finished parts for surface finish and flatness. Sheets can also be easily removed from the belt for length and squareness verification. The Conveyor has the ability to direct cut parts to the Stacker, or on command divert to a Scrap Cart, which makes disposing of coil head and tail ends quick and easy.

Automatic Sheet Stacker: Cut sheets are sent from the Inspection/Reject Conveyor into an Automatic Sheet Stacker. Sheets are supported on a set of non-marking roller "flippers" until the sheet is released directly above the stack. The sheet support flippers are quickly opened and closed by air cylinders. A Hydraulic Elevating Stack Table raises the sheet pack close to the sheet release height to minimize sheet drop distance. The Table automatically lowers as the sheet stack height builds-up. An air float system generates an air film that helps support light gauge sheets during the stacking sequence. Pushbutton adjustable side skirts and end stop contain the sheet stacks and produce solid-block packages. A Power Pallet Injector that positions fresh pallet into the Stacker minimizes pallet loading time. Pallet size is programmed into a controller and the pallet is automatically injected and centered in the Stacker.