|

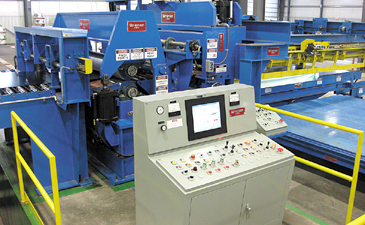

Cascadia's CTL produces all products in a Free-Loop Servo Feed operating mode. The Servo Feed draws the elveled strip from the free-loop and advances the strip to the pre-programmed length through the Hi-Speed cut-off Shear. Part lengths are precisely measured by an electronic encoder, while a microprocessor automatically establishes ideal acceleration/deceleration rates. Part length and batch count are operator programmed into the digital operating system. Servo Feeds compare favorably to "reciprocating hitch feeders" in productivity and reliability. Grabbing, releasing, sliding backwards, and re-grabbing consumes the majority of a reciprocating hitch feeder cycle time. By comparison the Servo Feed runs in one-direction . . . forward. The Servo-Feed's quick non-reciprocating operation, low acceleration/deceleration, an absence of chains, screws, clamps, slides, and related parts, makes it an outstanding performer with consistent close-tolerance accuracy, low operating cost, and bullet-proof reliability.

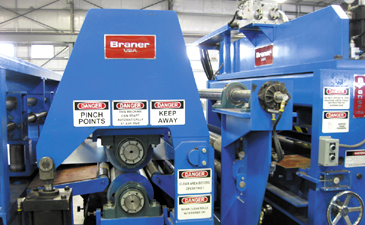

Cascadia's CTL Line features Braner/Loopco's fast and reliable Hi-Speed Hydraulic Shear. Adjustable blade gap allows Cascadia to quickly and easily establish the ideal blade clearance for shearing carbon steel and aluminum alloy throughout the .028" to .250" gauge range. Notable benefits of the Hi-Speed Hydraulic Shear are its exceptional reliability and virtual noiseless shearing cycle.

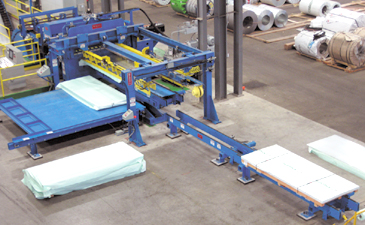

Straight-sided solid block sheet packs are produced by an Automatic Sheet Stacker that efficiently packages surface-critical coated steel and aluminum sheets without surface damage.

|

A Programmable Skid Injector eliminates having to muscle large heavy skids into the Stacker. A hydraulic pusher injects skids placed on the Injector Table onto the Elevating Stack Table. The skid size is entered into a programmable controller and the pusher automatically aligns the skid on the centerline of the Stack Table.

A finished sheet pack awaits removal while a new pack is being generated in the Stacker. A fresh skid placed on the Injector Table awaits injection into the Stacker.

Panel-flat 14-gauge x 14.500" wide x 180" long sheets stacked in straight-sided solid block sheet packs.

Precise tolerance, panel-flat sheets, , solid-block packages , outstanding performance , and bullet-proof reliability made Cascadia Metals' choice of a Braner/Loopco Cassette Leveler/Servo Feed Cut-to-Length Line a "no-brainer."

Cascadia Metals

7 International Drive

Longview, WA 98632

phone: (360) 425-8660 fax: (360) 577-9186

www.cmetals.com

|