Engineering Excellence

Advanced Technology Engineered Coil Processing Systems

Stretch Levelers can be installed in heavy-gauge hot rolled coil Cut-to-Length Lines to operate in conjunction with a Roller Leveler to produce a flat strip with no spring-back memory. Stretch Levelers are utilized to relieve trapped stress in the strip by stretching the strip beyond its elastic limit. Stretch stress relieving reduces chances of spring-back when the strip is cut in succeeding production processes. With the strip at a full stop, a fixed and a shiftable Gripper Frame installed 20 to 40-feet apart grips the strip between them. With the strip firmly gripped in both Frames, the shiftable Frame pulls away from the fixed Frame and stretches the strip. The stretched strip is released and relaxed, and the strip is fed forward 20 to 40 feet for the next stretch cycle.

Braner/Loopco Stretch Levelers are equipped with proprietary non-marking high-friction gripper pads that guarantee no marks in the material during the grip and stretch cycle. Consumable gripper cover pads often used by other brands to increase friction and avoid objectionable marking are not needed with Braner/Loopco Stretchers.

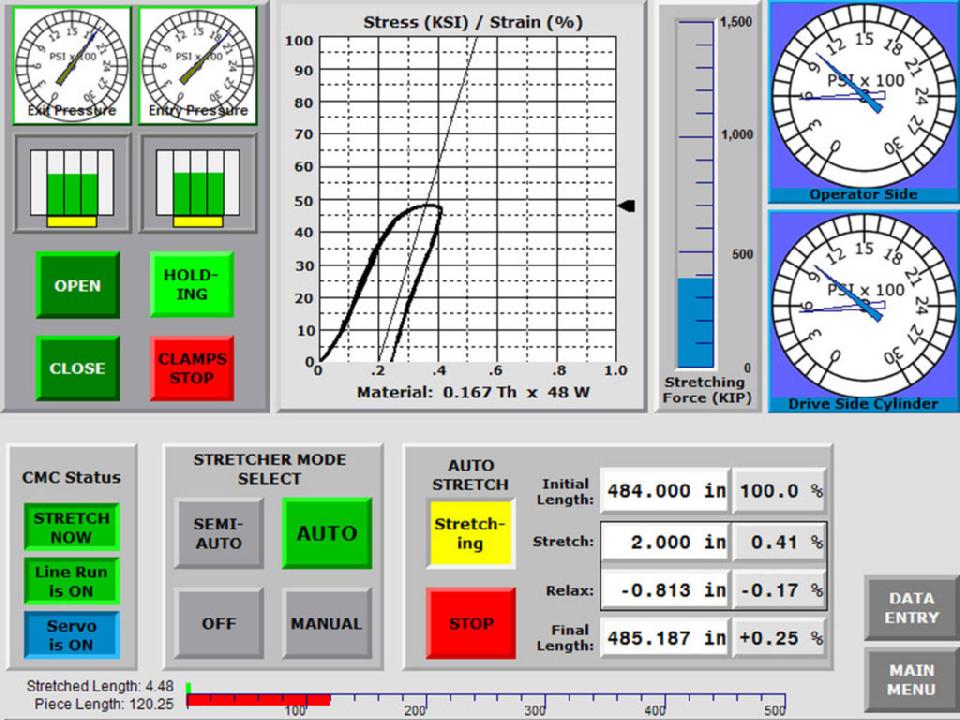

The stretch cycle is continuously monitored via proprietary real-time “Tensiometer” controls that accurately controls yield point elongation and avoids under and over stretching.

Braner/Loopco Stretch Levelers are equipped with proprietary non-marking high-friction gripper pads that guarantee no marks in the material during the grip and stretch cycle. Consumable gripper cover pads often used by other brands to increase friction and avoid objectionable marking are not needed with Braner/Loopco Stretchers.

The stretch cycle is continuously monitored via proprietary real-time “Tensiometer” controls that accurately controls yield point elongation and avoids under and over stretching.

© Copyright Braner USA, Inc.

9301 W. Bernice Avenue, Schiller Park, IL 60176

Phone: 847-671-6210, Fax: 847-671-0547 Email: branerusa1@braner.com

9301 W. Bernice Avenue, Schiller Park, IL 60176

Phone: 847-671-6210, Fax: 847-671-0547 Email: branerusa1@braner.com