|

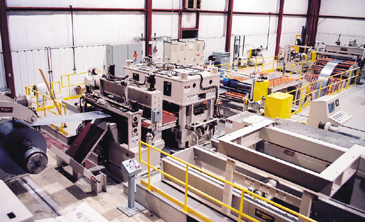

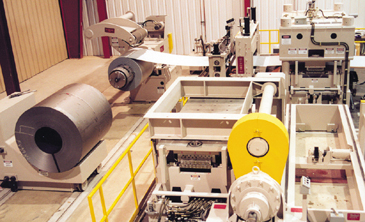

Burns Harbor, IN – J&F Steel

Corporation, a multi-facility carbon steel coil distributor and

coil processor has installed a new state-of-the-art Braner/Loopco

Cassette Leveler Servo-Feed Precision Multi-Blanking Line in its

newly expanded flagship facility in Burns Harbor, IN. The new

Multi-Blanking Line has the ability to convert 60,000# bare and

critical surface coated cold rolled steel coil in gauges from

.015" through .135" into 72" wide x 12’ long pattern sheets or

precision multi-blanks as small as 5" wide x 12" long. In

addition to the new Multi-Blanking Line, the J&F facility

contains four (4) Braner/Loopco Turret Headä slitting lines

(72", 60", 52", & 24"), and three (3) Braner/Loopco "Turret

Stacker" Automatic Packaging Lines.

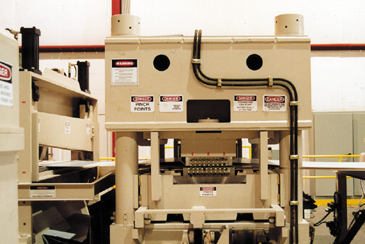

Hydraulic "Cassette" Leveler: The

new Multi-Blanking Line is equipped with Braner/Loopco’s

precision "Cassette" Leveler that employs advanced

electro-hydraulic motion-control technology to position 9

adjustable back-up flights and 17 work rolls to produce

panel-flat sheets and blanks. Hydraulic cylinders with

linear electronic transducers (rather than mechanical

jack-screws and sliding wedges) position the Leveler back-up

flights and work rolls to correct strip shape defects such as

coil-set, wavy-edge, and center-buckle. Computer controls are

employed to independently position the 18 back-up cylinders.

Independent control of the entry and exit ends of the back-up

flights allows the entry work rolls to be positioned and

contoured for aggressive shape correction at the entry end while

maintaining parallel exit end work rolls. This feature allows

precise shape correction without overworking the strip.

Independent positioning of the back-up flights across the work

roll face allows the work rolls to be "tilted" from side-to-side

to correct asymmetrical shape defects.

. .

|

The Leveler controls feature full automatic Leveler set-up based

upon gauge and yield strength inputs, a computer memory that

recalls previous Leveler set-up parameters (saving set-up

time when running partial coil orders), and a calibration

mode that automatically calibrates the Leveler after roll

grinding or periodic maintenance

The J&F Leveler is equipped with two (2)

interchangeable "Cassettes": a 1.250" x 6-Hi Cassette, and a

1.750" x 5-Hi Cassette. The smaller Cassette is utilized to

process a gauge range from .015" to .060", while the larger

Cassette is utilized for leveling .030" through .135" materials.

In addition to providing an extended leveling range, the

Cassette Leveler design simplifies Leveler maintenance by

allowing work roll and back-up maintenance to be accomplished

outside the Leveler frame rather than inside the frame where

many parts are inaccessible. The Leveler Cassettes are installed

and removed from the Leveler frame via an "Indexing Cassette

Injector Car". The Injector Car allows one Cassette to be

ejected and another installed in about one-minute. A Powered

"Cassette Opener" attached to the Injector Car simplifies

maintenance by opening an off-line Cassette like a "book",

exposing the work rolls and back-ups.

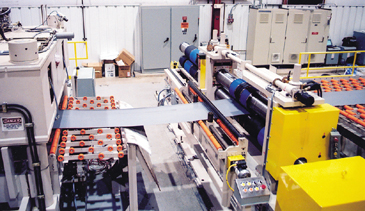

Precision Multi-Blank

Slitter: The J&F Multi-Blanking Line employs a

quick-change two-head "Turret Head"ä

slitter located immediately after the Cassette Leveler

(before the looping pit) to slit the leveled material into

multiple strips.

The Turret Head slitter is an accurate,

reliable, and maintenance-free slitter that with its precision

shimless tooling consistently produces strips to ±0.002" width

tolerance. While most multi-blank slitters require that the line

be shut down during the preparation of a slitter set-up, the

Turret slitter allows J&F to prepare the next multi-blank

slitter set-up while the line is running. The ability to

prepare the next set-up while the line is running significantly

improves multi-blanking line productivity by virtually

eliminating down time related to slitter set-ups. Once the

off-line slitter set-up is completed, production down time

related to changing slitter heads is one-minute.

|