|

Many multi-blanking slitters are installed

after the looping pit, slitting the strip in a

start-stop cycle synchronized with the strip feeder cycle.

By comparison, the J&F slitter is installed before

the looping pit, slitting the strip at a constant line speed

synchronized with the Cassette Leveler. By slitting at a uniform

non-stop line speed, J&F is able to avoid problems associated

with knife slippage and produce uniform high-quality

close-tolerance slit edges on all multi-blanks.

To minimize slitter set-up time, the J&F

Turret Head slitter employs a custom designed precision shimless

tooling package specifically designed for side trimming and the

production of multi-blanks 5" and wider. The Turret Head

slitter, with the custom tooling package, is able to produce

precise ±.002" slit width tolerances while also allowing

multi-blank set-ups to be accomplished in 1/4 to 1/3 the time

normally required to complete a typical coil slitter set-up.

Depending upon the number of cuts and widths, coil slitter

set-ups can take as long as 45 minutes to complete. But with the

quick loading and lightweight tooling design of the Turret

slitter plus the advantage of the custom multi-blank tooling,

J&F can finish a typical multi-blank set-up in about 15 minutes.

Special spacers that are 53% lighter than conventional

spacers are a key element in the custom-tooling package, and the

lightweight spacer design makes extra-wide spacers feasible.

Employing extra-wide spacers to generate 2 to 5 multi-blank

strips dramatically reduces spacer "piece-count" and set-up time

is reduced. For example, a shimless coil slitter set-up for

eleven 3.125" and eight 2.875" x .030" strips would need 283

spacers and about 45 minutes to set-up. With J&F’s custom

tooling package, a multi-blanking set-up for one 30.000" and one

29.500" x .030" blank would need only 43 spacers. 43 spacers

versus 283, or 1/6th the number of pieces. Since set-up time is

directly proportional to the number of pieces that have to be

loaded and removed, it makes sense that less pieces means less

set-up time. The J&F Steel Turret Head slitter equipped with the

multi-blank tooling package can be re-tooled for most orders in

15 minutes. Since it takes more than 15 minutes to process any

size multi-blanking run, the slitter set-up can be finished

before it is needed. More importantly, J&F is able to re-tool

for the next order while the line is running, so no production

time is lost.

Precision Electronic Servo Feed:

The J&F Multi-Blanking Line employs a Precision Servo Feed to

feed and measure strips for cut-off. The Servo Feed uses

high-traction non-marking feed rolls driven by a precision

electronic AC vector servo system to feed and measure the

strips. The feed rolls are full-width with back-up rolls that

eliminate feed roll deflection. A state-of-the-art motion

control system capable of producing consistent sheet and blank

length tolerances of

±.005" is employed for feed length measurement. |

The electronic motion control receives feed

roll position data from an electronic encoder, and the position

information is instantly transformed into accelerate,

decelerate, and full stop commands based upon the feed length.

The motion-control system automatically computes the ideal

production speed based upon the part length entered into the

operator data panel. An adjustable acceleration/deceleration

control is provided to compensate for various material surface

conditions.

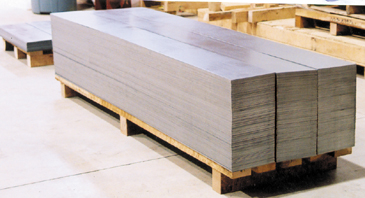

Finished pattern sheets and multi-blanks are

packaged in a Programmable Air Float Stacker. Multiple blanks

are separated in compartments formed by steel ribbon dividers

that are automatically positioned to match the blank sizes via

electronic servomotors. Defective sheets and blanks can be

diverted on-the-fly and sent from the Stacker to a scrap reject

station. Completed stacks are discharged from the Stacker and

weighed prior to removal

J&F

Steel Corporation

310 Tech Drive

Burns Harbor, IN 46304

phone: 219-764-3500 fax: 219-764-0073

http://www.j-fsteel.com

|