|

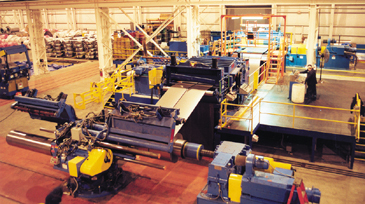

Jeffersonville, IN – Eagle Steel Products,

Inc, a flat rolled steel distributor and coil processor located

near Louisville, KY, has installed a new precision double-loop

Turret Head coil slitting & surface inspection line with in-line

shape correction capability in its expanded 170,000 square foot

barge and rail serviced facility on the Ohio River in

Jeffersonville, IN. Eagle Steel provides high-quality precision

coil slitting, surface inspection, and leveling services for

carbon and stainless steel producers, automotive and appliance

manufacturers, as well as other OEMs.

The new Braner/Loopco slitting/inspection

line is capable of processing 80,000# x 76" wide surface

critical coated steel as well as 300 and 400 series stainless

steel coil in gauges from .009" through .187" at speeds to 1,200

FPM.

76" Slitting LIne (Inspection Station in

background)

Double-Loop Processing – The line has

the ability to process coils in tight line, single loop, and

double-loop operating modes. Based upon material, gauge, and

duty (surface inspection, edge trim, multi-cut slitting), Eagle

Steel can select the operating mode that would produce the best

quality and best operating efficiency. For example, the tight

line mode is commonly utilized for edge trimming and surface

inspection. Mid-gauge cold rolled is normally processed in the

single loop mode, and double-loop is commonly selected for

processing light gauge surface critical coil. In the double-loop

mode the DC motor driven Uncoiler drives the strip into a free

loop ahead of the slitter, causing the strip to be steered and

slit under zero back tension conditions. Zero back tension

produces tighter slit width tolerances because the strip lays

flat into the slitter knives. Zero back tension produces a

better quality slit edge because slitter knife slippage is

virtually eliminated. Edge trim width can be reduced with zero

back tension since the strip can be side guided into the slitter

without the fear of rolled-up edges. Higher slitting speeds can

be achieved and entry tension induced camber can be eliminated

because thin gauge coil "wobble" (coil OD eccentricity) is

isolated from the slitter by the free-loop.

|

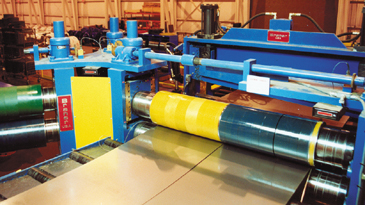

Loop control Uncoiler with Outboard Support

Turret Head Slitter™ – The Eagle Steel line is equipped

with a quick-change Turret Head Slitter with three (3) 9.500"

heads. The Turret Head Slitter is easier and faster to re-tool

than any other slitter design, and has the added benefit of

changing heads in one-minute. A 300 HP DC motor driving the

Turret Head Slitter allows single loop slitting of up to 24 cuts

in .075" at 1,200 FPM.

Precision Triple Turret Head Slitter

Surface Inspection – Processing

surface critical material often requires that coils be quality

inspected for surface defects. The Eagle Steel line is equipped

with a surface inspection station equipped with multiple

fluorescent lamp banks as well as high-intensity strobe lamps to

highlight surface scratches, dents, or other surface defects.

Surface defects are visually identified, located, and recorded

by an inspector as the coil is processed.

In-Line Shape Correction – The Eagle

Steel line is equipped with a Cluster Leveler™ capable of

eliminating strip shape defects such as center buckle, wavy

edges, and cross-bow from the strip. The Cluster Leveler is a

corrective roller leveler with adjustable back-ups supporting

work rolls that range in size from 3.000" to 1.500". The

patented work roll design gives the Cluster Leveler the unique

ability to eliminate strip shape defects through the entire

.009" to .187" gauge range by applying large or small diameter

work rolls to the strip depending on gauge and yield strength. A

PLC eliminates leveler set-up trial and error time by making the

set-up fully automatic.

|