|

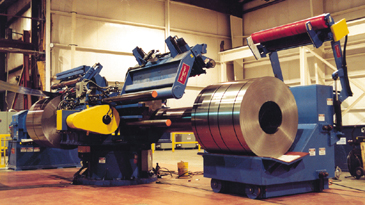

Shape Correction Cluster Leveler

Turret Recoiler – In

order to address one of the most time-consuming tasks in a

slitting operation, slit coil OD banding and preparation for

coil unloading, the Eagle Steel line is equipped with a 300 HP

Turret Recoiler with two rewind drums and two Overarm

Separators. After a coil is rewound, the 300 HP drive

disconnects from the rewind drum and the Recoiler rotates 180

degrees, positioning the finished coil at the unload station

while positioning an empty drum at the slitting station. OD

banding and coil unloading is accomplished while the strips are

fed into and rewound on the opposite drum. Down time is

virtually eliminated. To speed-up OD banding, both Overarms are

equipped with Tail Hold-Downs, a set of adjustable polyurethane

pads that are pressed against the coil OD by hydraulic

cylinders. The Tail Hold-Downs prevent the coil tails from

clock-springing and provide a clear path for feeding the OD band

around the coil. Each Turret Recoiler drum has an independent

drive that allows the coil to be rotated at the unload station.

Turret Recoiler w/Speed-Load Fillers

One-Minute Speed-Load Recoiler Fillers

– Eagle Steel produces 20" and 24" ID slit coils according to

their customer’s specifications. It is common knowledge that

changing coil IDs can generate huge down time costs

because switching from 20" to

24" or vice-versa requires "fillers’ to be installed and removed

from the Recoiler drum, and attaching or removing Recoiler

fillers will typically waste 15-20 minutes of production time.

The Eagle Steel

|

line is equipped with Braner/Loopco’s

exclusive "One-Minute Speed-Load Fillers" that switches coil IDs

from 20" to 24" on one-minute. Unlike the common "filler plates"

that are comprised of 3-4 individual segments that are secured

to the Recoiler drum with 4-6 bolts per segment, the Braner/Loopco

Speed-Load Fillers is one-piece hardened steel assembly that

uses no Recoiler drum attachment bolts. The Speed-Load is

slipped on the Recoiler drum to produce 24" ID coils, and

slipped off the drum to produce 20" ID coils. Each cycle takes

one-minute instead of 15-20 minutes, allowing Eagle Steel to

change the coil ID with no down time.

Slit Coil Packaging Line

Automatic Coil Packaging – The Eagle

Steel slitting line is equipped with a slit coil packaging

system capable of handling slit coils fro, 1" to 24" wide,

weighing up to 20,000#. An operatorless Programmable Downender

removes slit coils from a 4 Arm Turnstile and places the coils

onto a powered staging conveyor. Individual slit coils widths

are programmed into the Downender controller, and the Downender

automatically unloads all the coils unattended. From the staging

conveyor, coils are fed into the Coiltech/Signode strapping

machine where 3/4" radial bands are applied in a semi-automatic

manner. Spacer blocks are placed and the coil is weighed while

the coil is on the strapping machine. The strapped coil is then

sent into the coil stacker where it is automatically removed

from the table and deposited onto any of eight stacking stations

on a rotatable turntable. After a coil package is completed on

the turntable, the package is discharged onto a runout conveyor

where the entire package is weighed. The package is sent onto a

runout conveyor where it can be removed and shipped as a

palletized package, or upended 90 degrees and removed and

shipped cylinder fashion.

5150 Loop Road

Jefferson, IN 47130-8412

phone: 812-282-4770 fax: 812-282-5873

www.eaglesteel.net |