Huger, SC - Steel Technologies has installed a high-production close-tolerance Multi-Blanking Line in its Huger, SC coil processing facility. The Multi-Blanking line has the ability to convert 80,000# x 72" wide bare and coated carbon and stainless steel coil into panel-flat sheets and precision blanks in gauges from .024" through .135". Equipped with the latest high cyclic rate Servo Feed-DC Shear technology, the line can operate at more than 75-cycles minute. The new Multi-Blanking Line joins a Braner/Loopco 80,000# x 72" double-loop Triple Turret Head™ Slitting Line in the Huger, SC plant.

Hydraulic Leveler, Turret Head™ Slitter, Servo-Feed, DC-Shear Multi-Blanking Line

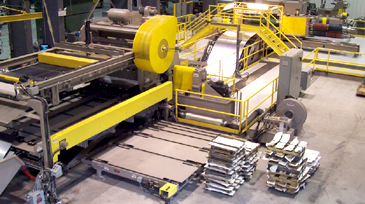

72" Multi-Blanking Line Exit End View

Precision Hydraulic Leveler: A massive 4-post, 17-roll x 9-flight x 5-Hi Roller Leveler produces panel flat shape corrected parts for Steel Tech. All Leveler work roll and back-up adjustments are accomplished by microprocessor controlled hydraulic cylinders, instead of electric motors, gear reducers, and sliding wedges. Hydraulic cylinders positioned at the entry and exit ends of each back-up flight accomplish entry-exit work roll gap and side-to-side shape correction roll bend adjustments. Electronic linear transducers sense the position of each hydraulic cylinder. Adjusting the entry end and exit end cylinder elevations causes the work rolls to be "tilted" front-to-back for coil-set correction. Adjusting cylinder elevations from side-to-side across the Leveler roll face causes the back-up flights to be set-up for "roll-bending." Accurate roll bend is necessary for wavy-edge and center-buckle shape correction. Hydraulic Leveler benefits include elimination of mechanical backlash, ability to precisely repeat roll position settings, reduced maintenance, and set-up automation.

Computer Leveler Controls: 18-hydraulic cylinders are used to adjust the Steel Tech Leveler for strip shape correction. Because there are so many possible back-up and work roll position adjustments, the Hydraulic Leveler is controlled by a PC computer.