|

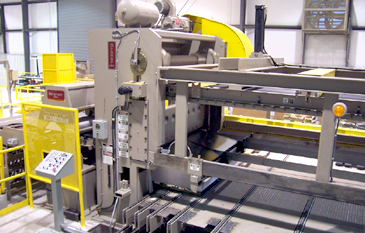

Precision Electronic Servo Feed: High-traction non-marking feed rolls with a microprocessor AC servo drive feeds and measures parts to +/-0.005" length tolerance. The Servo Feed draws multiple strips from the free-loop and feeds to a pre-set length into the Shear. Part length is precisely measured by an electronic encoder, while a microprocessor establishes acceleration/deceleration rates. Sheet length and batch count are easily and quickly entered into the digital operating system. Servo Feeds compare favorably to "reciprocating mechanical feeders" in cyclic production rates and maintenance requirements. A reciprocating mechanical feeder grabs the strip, shoves forward to a positive stop, grabs again with holding clamps, shoves the reciprocating clamp backwards, grabs again, and releases the holding clamp before starting another feed cycle. Grabbing, releasing, sliding backwards, and re-grabbing consume the majority of a reciprocating feeder cycle time. By comparison a Servo Feed simply rotates feed rolls in one direction. A reciprocating mechanical feed's productivity is diminished further when making multiple feed strokes for long parts. The Servo Feed's non-reciprocating operation, low acceleration/deceleration rate, few moving parts, and a total absence of chains, length adjust screws, shock absorbers, limit switches, valves, pumps, slides, clamps, & hydraulic hoses gives it consistent accuracy and "bullet-proof" reliability.

Hi-Cyclic Rate Precision Electronic AC Servo Feed

100-Cycle/Minute DC Shear: The Steel Tech line includes a massive top driven mechanical bow-tie Shear. The Shear is powered by a variable speed DC motor. The DC Shear produces pattern size sheets in a 60-stroke/minute "clutch-brake" mode and short blanks in a "non-stop continuous-stroke mode" up to 100-cycles/minute. Combined with the super high-cyclic rate capability of the Servo Feed, the non-stop continuous DC Shear cycle offers unrivaled close-tolerance small blank productivity. In the "continuous" shearing cycle, the crankshaft runs non-stop at a speed and SPM synchronized with the Servo Feed. The Servo's "feed forward" cycle begins as soon as the upper shear blade clears the material on its up stroke. The Servo continues to feed the strips well past the Shear's top dead center and stops only when the shear blade approaches the strip in its down stroke. The simultaneous feed-shear cycle generates parts per-minute productivity twice as high as any other feed-shear method.

Servo Feed DC Shear Multi-Blank Stacker

|

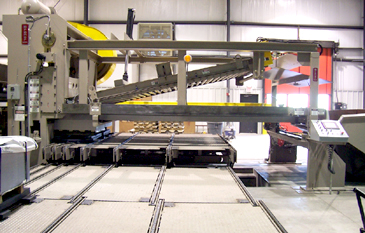

Programmable Multi-Blank Stacker w/ Programmable Reject: The Stacker features full automatic multi-blank set-up via microprocessor controlled AC servo motors. The multi-blank blank dividers are automatically positioned to produce "solid-block" straight-sided single sheet and multi-blank packs. Hydraulic locks secure the dividers in the stacking position. An air float system generates a thin air film that guards against sheet-on-sheet scratching during the stacking sequence. A "reject" system sends heads, tails, and other non-prime parts outside the Stacker into a scrap bin. Reject part length and reject sequence is fully programmable.

Programmable Multi-Blank Stacker w/ Auto Reject

Stacker Unloading Finished Multi-Blank Packs

Proven ability to generat huge quantities of precise width, precise length, and panel flat parts per minute, PLUS massive construction and bullet-proof reliability make the choice of a Braner/Loopco Multi-Blanking Line a "no-brainer."

Steel Technologies, Inc.

1220 South Steel Circle

Huger, SC 29450

phone: (843) 336-3999 fax: (843) 336-4701

www.steeltechnologies.com

|