Saline, MI - ThyssenKrupp Materials NA, a non-ferrous coil distributor and processor has installed a Braner/Loopco Double-Loop Triple Turret Head™ Coil Slitting and Slit Coil Packaging System in its new Saline, MI, facility. The new Slitting Line is capable of processing stainless, aluminum, copper, & brass coils in gauges from .010" through .250" at slitting speeds to 1,000 FPM. Coil sizes can range up to 40,000# x 60" wide up to 74" OD with master coil and slit coil IDs of 16" and 20".

Hi-Production Triple Turret Head™ Stainless & Aluminum Coil Slitting Line.

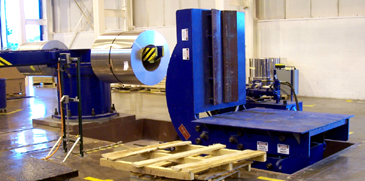

Entry Coil Handling: ThyssenKrupp receives many of its thin-gauge non-ferrous master coils eye axis vertical on pallets. A Coil Car-Tipper is employed to upend palletized coils to the eye horizontal position for processing. The Coil Car-Tipper efficiently "tips" the coil 90-degrees and loads the coil onto an Entry Storage Horn where 4-coils can be staged ahead of the Slitting Line.

Coil Car-Tipper upends palletized coils and loads onto a 4-Arm Entry Storage Horn.

Paper-Interleaved Master Coils: Surface-critical stainless and aluminum coils often contain paper interleaved between coil wraps. The ThyssenKrupp Slitting Line is equipped with a Paper Winder that neatly rewinds interleaved paper from the master coil as it is being processed.

Interleaved Paper Winder efficiently handles interleaved paper.

Single/Double-Loop Entry Section: The Slitting Line employs Braner/Loopco's hi-pass line arrangement that places the strip processing equipment above the coil OD to eliminate cross-breaks from forced reverse bending the strip. Hi-pass line saves floor space, provides excellent strip tracking, and allows the DC motor driven Uncoiler to operate in single and double-loop modes with no entry looping pit.