Close coupled Pass Line Roll provides excellent strip tracking to the Recoiler.

Recoiler produces 16" and 20" ID coils with or without cardboard cores.

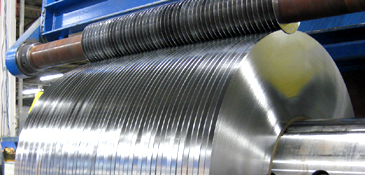

Winding 50-cuts 5/8" wide x .007" into tight, perfectly slit coils.

Rotary Deck Exit Coil Car: An Exit Coil Car unloads coils from the Recoiler and transports them to the Pack Line. The Car has a unique rotary V-deck that can position coils for CW or CCW orintation on the shipping pallet. The Car is operated from a wireless radio control.

Quality, Performance, Bullet-Proof Reliability, know-how from building nearly 600 Slitting Lines, plus superb technical support made Berlin Metals' selection of a Braner/Loopco Turret Head™ Slitting Line over all others a "no-brainer".

Berlin Metals, LLC

3200 Sheffield Avenue

Hammond, IN 46327

phone: (800) 754-8867 fax: (664) 219-0692

www.berlinmetals.com