Ranch Cucamonga, CA - Searing Industries, a premier USA manufacturer of mechanical, ornamental, and heavy wall welded structural steel tubing has installed a new high-performance 1/2" Single-Loop Turret Head™ Slitting Line in its 300,000+ square foot manufacturing facility in Ranch Cucamonga, CA. The new 1/2" Slitting Line joins two additional Braner/Loopco Slitting lines at Searing Industries. The massive new Slitting Line, which will be dedicated primarily for producing high-quality heavy-gauge slit coil for Searing's mechanical and structural tube mills, has the ability to process 60,000# hot rolled black, pickled, cold rolled and galvanized carbon steel coils in gauges from .060" through 1/2" in tight-line and single-loop operating modes.

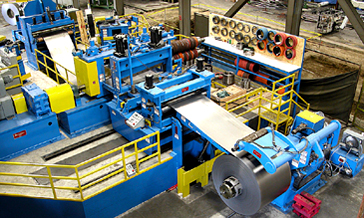

Single-Loop Turret Head™ Slitting Line processes hot rolled and cold rolled carbon steel coils in gauges from .060" through 1/2" in tight-line and single-loop operating modes.

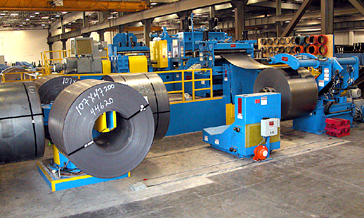

Four Arm Turnstiles stage and store 80" diameter coils at the entry and exit ends of Searing's 1/2" Slitting Line.

Compact High Pass Line: Searing Industries' new 1/2" Slitting Line is an example of Braner/Loopco's high-performance compact high pass line arrangement that positions the Uncoiler and Recoiler at floor level with the processing section installed at an elevation to match the largest coil OD. The arrangement allows the strip to be processed through the line without forced reverse bending against the natural coil set. Compact high pass line benefits include quick and easy coil threading, elimination of reverse-bend coil-breaks, and elimination of strip surface damage from deflector roll scuffing. The arrangement allows the Uncoiler and Recoiler to be tucked-in close to the Entry and Exit Units, conserving floor space, speeding coil threading, and providing excellent coil tracking necessary to generate tight and straight side-wall slit coils.