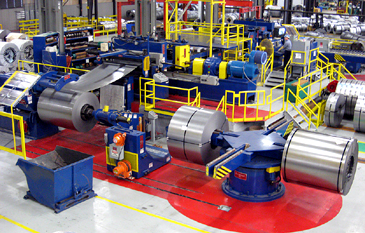

LaVergne, TN - SteelSummit, a subsidiary of Sumitomo Corporation of America, has installed a high-performance Braner/Loopco Double-Loop turret Head™ Slitting and Slit Coil Packaging Line, featuring a Shape-Correction Cluster Leveler™ in its LaVergne, TN coil processing facility near Nashville. The Double-Loop Slitting Line joins three (3) other Braner/Loopco Single-Loop Turret Head™ Slitting Lines in SteelSummit's LaVergne, TN facility.

SteelSummit's latest high-performance slitting line employs 600 horsepower for processing surface-critical automotive coils weighing 70,000# in widths to 76" at slitting speeds to 1,000 FPM. Coil gauge capacity is from .012" minimum through .187".

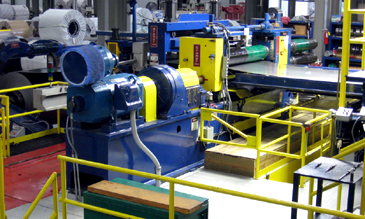

The DC motor driven loop-control Uncoiler fitted with an Outboard Support drives the coil into a free-loop ahead of the slitter in the Double-Loop tension-free slitting mode. Tension-free slitting eliminates tooling induced strip surface scuffing, and generates tighter tolerance slit widths. Single-Loop and two (2) Tight-Line operating modes are employed for slitting medium and heavier gauge coil.

SteelSummit's Turret Head™ Slitter produces close-tolerance slit strips with minimum burr throughout the entire range of gauges and mechanical properties. The unique Turret Head™ Slitter design allows for quick re-tooling and a 2-minute head change cycle. Reliability is bullet-proof.