In order to maintain exceptional surface-critical quality standards, SteelSummit's Non-Marking Tensioner is equipped with quick-change tension roll cartridges that are employed for dedicated critical quality products.

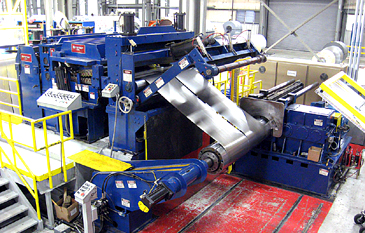

The 70,000# x 76" Recoiler is equipped with a 20" diameter rewind drum mounted on a 14" shaft and driven from a two-ratio parallel shaft helical gear reducer by a 300 HP motor. The Recoiler is equipped with an Outboard Support that eliminates shaft deflection and resulting Recoiler drum misalignment. The Overarm Separator is supported from the inboard and outboard ends in order to assure square and parallel slit coil guiding. An exit end Shear efficiently splits coil ODs without having to re-thread the line.

The Slitting Line can produce slit coils with 20" and 24" IDs. A patented Speed-Load Filler allows SteelSummit to change coil IDs in 2-minutes, a task that requires 15-20 minutes with older technology "bolt-on" style filler plates.